PRODUCTION PROCESSING

MORE DETAILS

1. Design

2. Raw materials

Purchase standard Q235 steel, plastic, rubber and other materials according to product requirements.

3. Cutting

Use laser cutting machines to cut pipes with high cutting accuracy, smooth cuts, and cuts into specific shapes.

4. Stamping

Use high-precision bending technology and precise bending to ensure stable structure and beautiful appearance.

5. Welding

Use manipulator welding to weld different parts into a frame to improve the integrity and strength of welding.

6. Surface Treatment

Sandblast to remove rust, then electrostatic spray with three-coat two-bake process for corrosion resistance and aesthetic finish.

7. Assembly and testing

Assemble the parts according to the drawings, check the products and test whether the equipment functions normally.

8. Packaging and storage

Use shockproof and moisture-proof packaging materials to avoid damage during transportation.

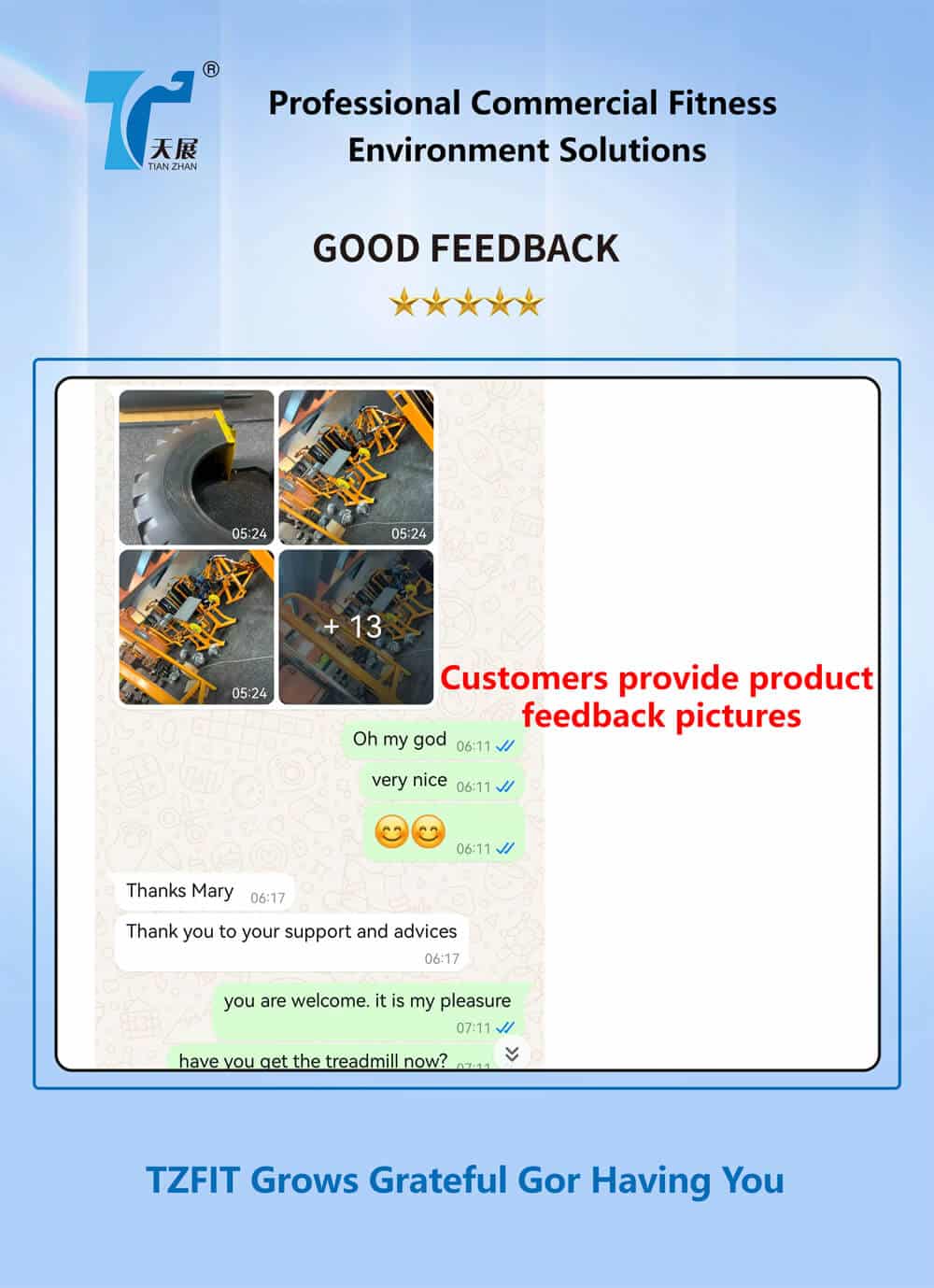

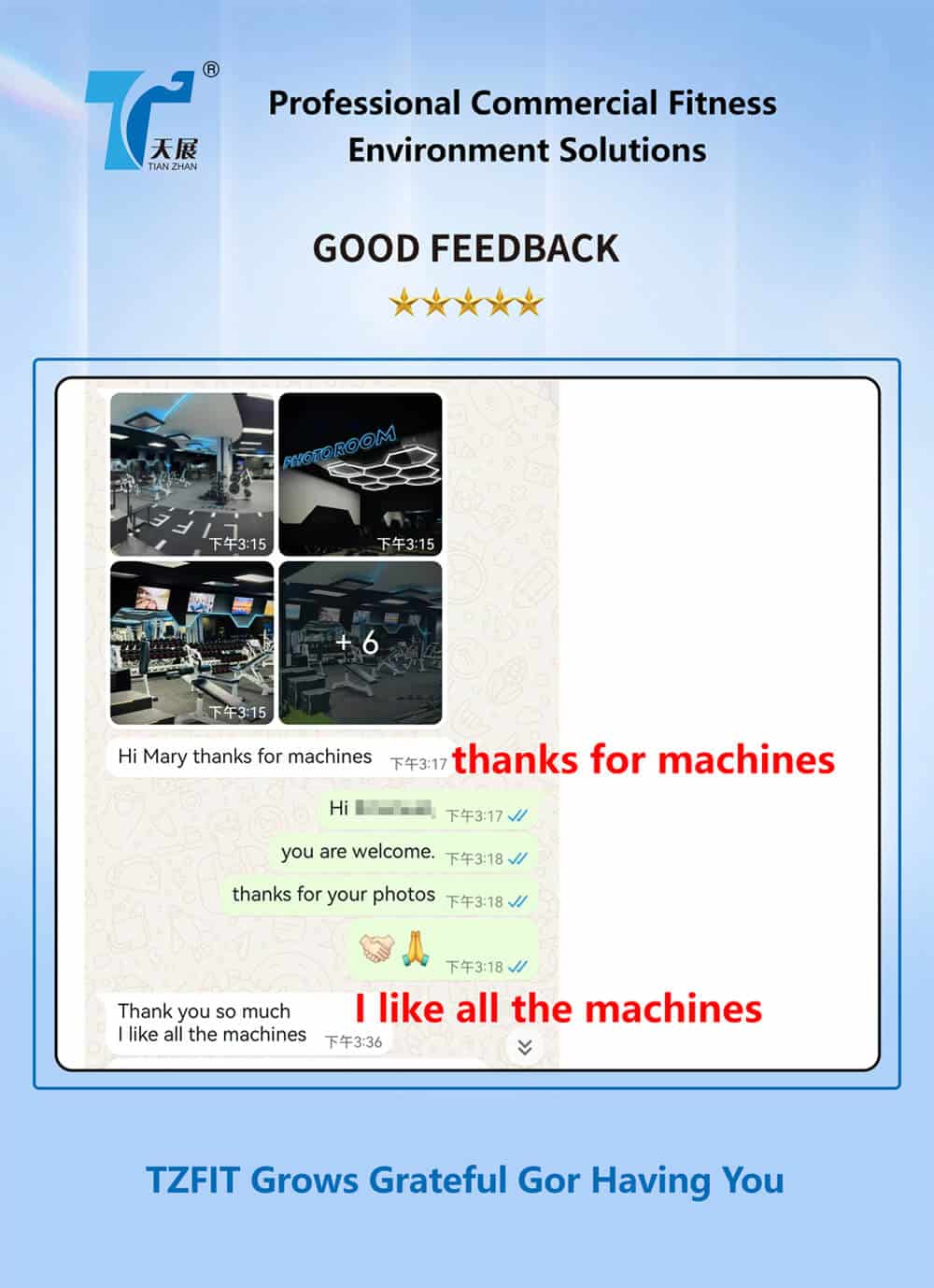

what clients say to us

TZ Blog